Equipped with a proprietary hybrid radial tangerine phase plug, the integrated HF compression driver has been designed to deliver a smooth coherent wavefront at the horn entrance in all working frequency ranges with a high level of manufacturing consistency. The phase plug, with its short openings and high flare rate value, assures low distortion and remarkable improvements in mid-high frequency reproduction. A copper sleeve reduces inductance value above 10kHz, improving phase and impedance linearization. The HF diaphragm assembly is made by proprietary treated Polyethylene material. Thanks to its superior diaphragm dimensional stability, Polyethylene shows constant behavior during its whole working life. Moreover, this particular material with its very high value of elasticity modulus is capable of superior transient and intermodulation distortion response. The flat suspension shape is designed to maintain low stiffness and low mid-band distortion and response. An EDGE-wound aluminum voice coil wound on proprietary treated Nomex completes the diaphragm assembly. Thanks to its physical properties, the proprietary treated Nomex former shows a 30% higher value of tensile elongation at a working operative temperature when compared to Kapton. This feature enables proper energy transfer control from the voice coil to the dome in real working conditions. Moreover, this proprietary former material is suitable for use in damp and wet environments. A specific dedicated HF driver throat design has also been chosen, maximizing the cone’s profile coupling.

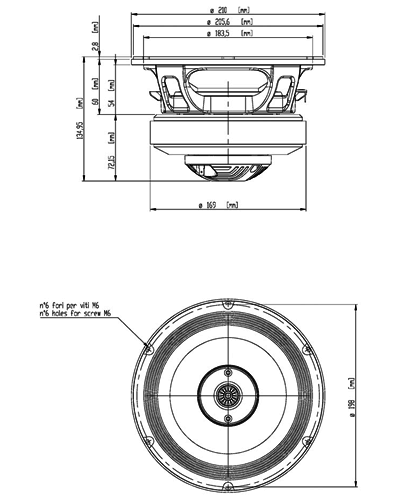

Driver diagram

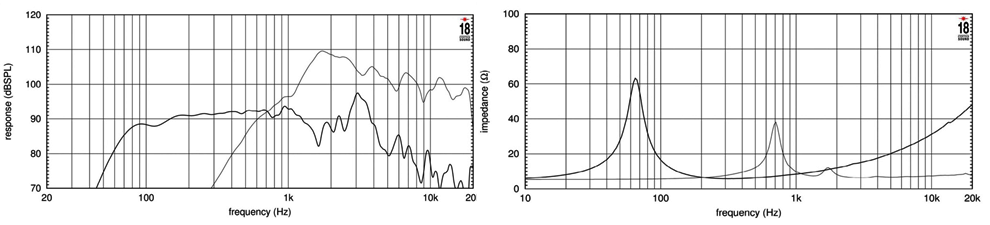

Driver chart

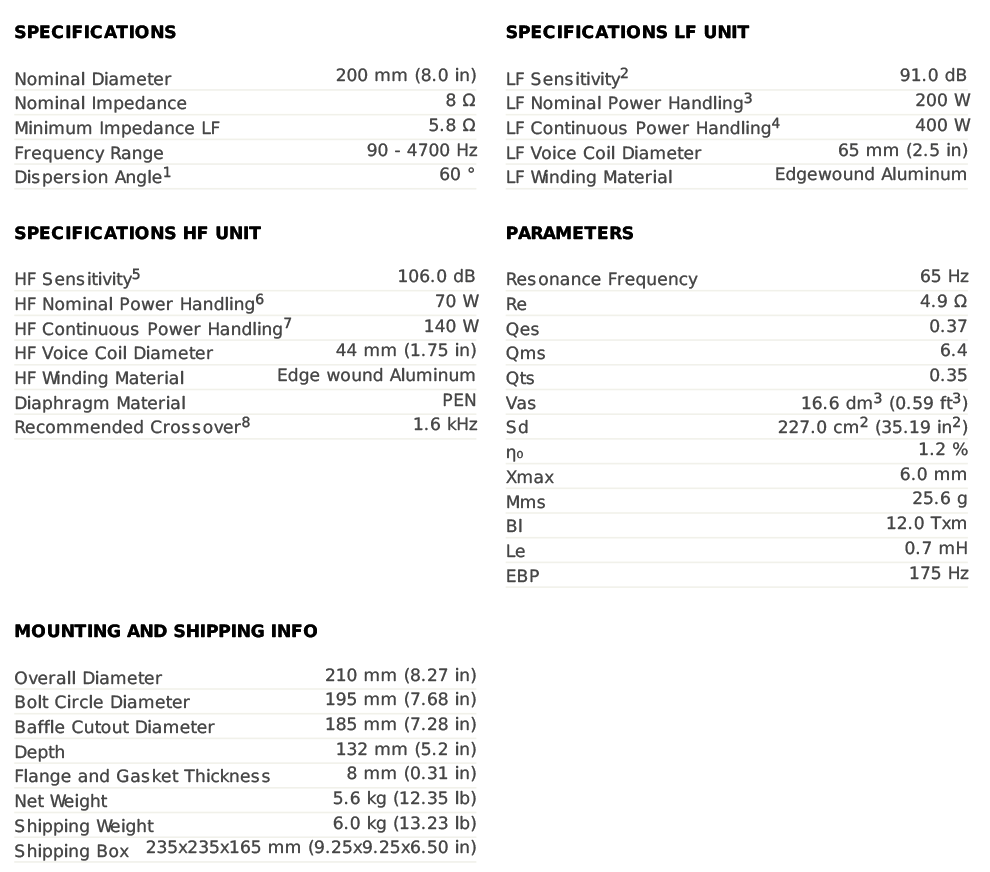

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct