In essence, a high strength Fiberglas former is used to carry windings on both the outer and inner surfaces to achieve a mass balanced coil. This results in an extremely linear motor assembly, which, in conjunction with the highly advanced design of the magnetic structure, provides a high force factor or BL. The high frequency driver incorporates a polyester material diaphragm for best movement and stress control; the special radialribs increase stiffness avoiding uncontrolled vibration modes in the usable frequency range. An EDGE-wound copper clad aluminum voice coil wounded on treated Nomex completes the diaphragm assembly. A computer aided FEA has been used in order to maximize the cone profile coupling and to control the energy in the desired frequency range. A dedicated high quality passive crossover network is available upon request. With the increasing use of outdoor audio events, the ability to perform in humid environments is another feature of the 8CX400F. This is achieved by means of exclusively developed humidity repellent cone treatment.

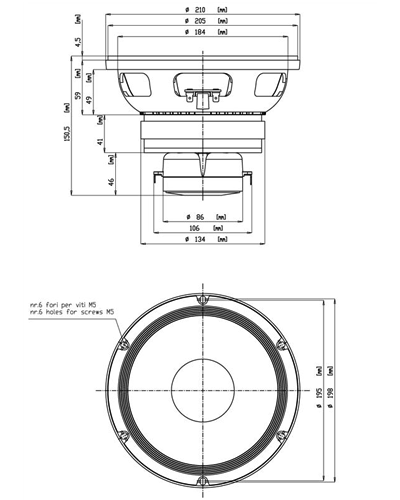

Driver diagram

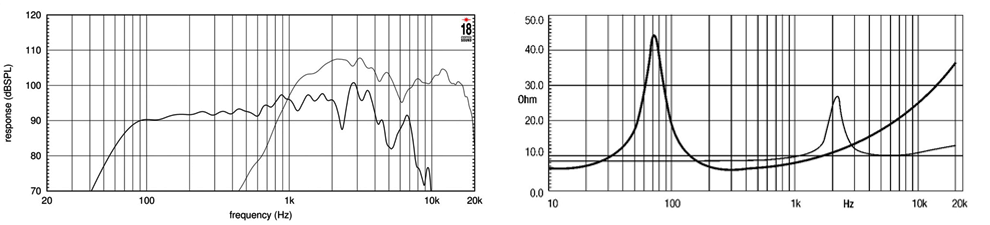

Driver chart

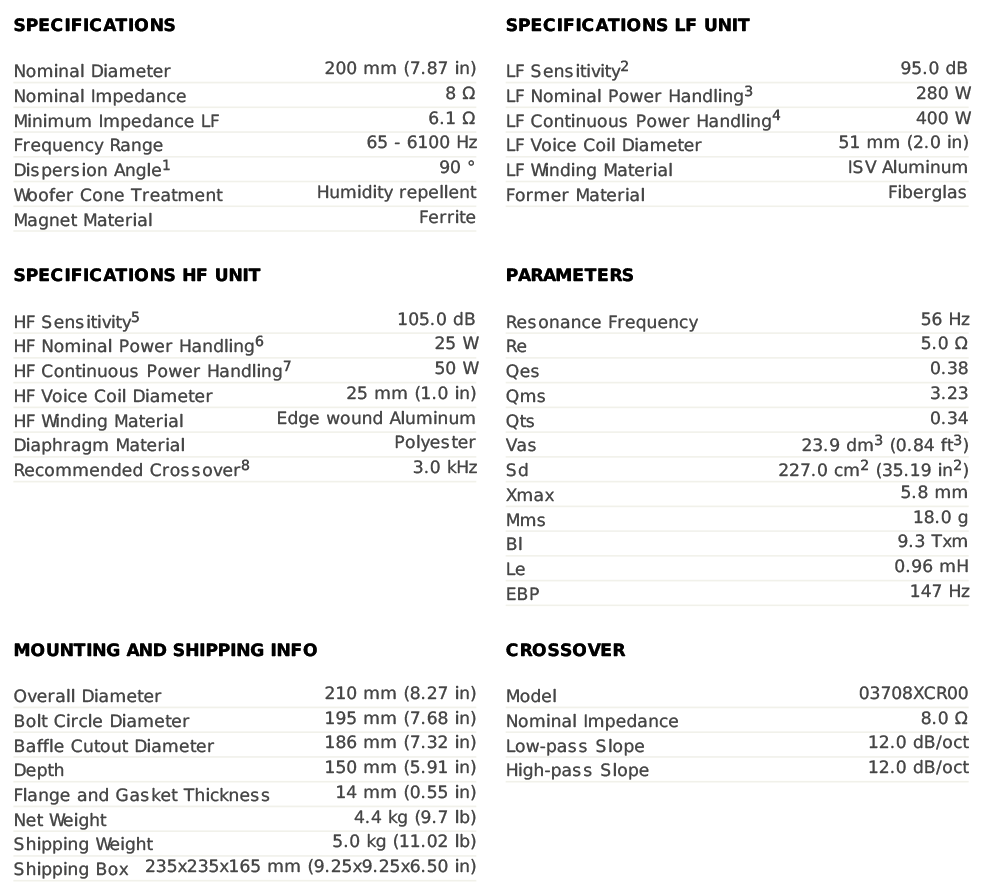

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct