The sound chamber and rear cover are aluminum injection-molded parts which assure high mechanical reliability and optimum thermal exchange. The lightweight neodymium magnetic structure has been developed to assure high flux concentration and excellent thermal exchange thanks to the neodymium external magnet configuration. This is considerably more efficient than usual inner-pole neodymium magnet topology. The unit employs a Kapton diaphragm with a 2-inch diameter round copper voice coil. A precise diaphragm structure and alignment mechanism allows easy and cost-effective repair in case of diaphragm failure. The horn belongs to the reflex-type family with a rectangular polycarbonate molded structure. It provides an optimum sound level output (121dB measured at 1.8kHz, 3 meter on axis, rated power) and features a directed dispersion range of 120°H x 140°V (1kHz octave band), in order to assure a high intensity acoustic field. A special automotive standard surface protection treatment has been applied to all metal parts, assuring stronger resistance against the corrosive effects of salts and oxidization. Hence, the unit is also suitable for use in inclement weather conditions.

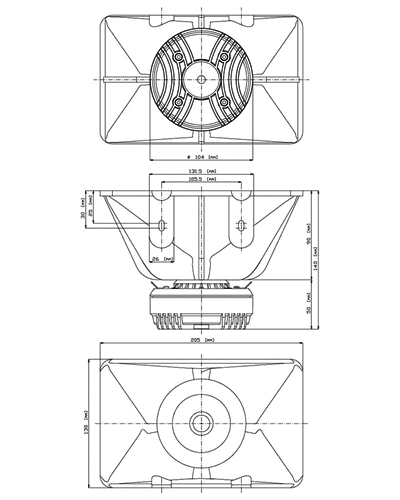

Driver diagram

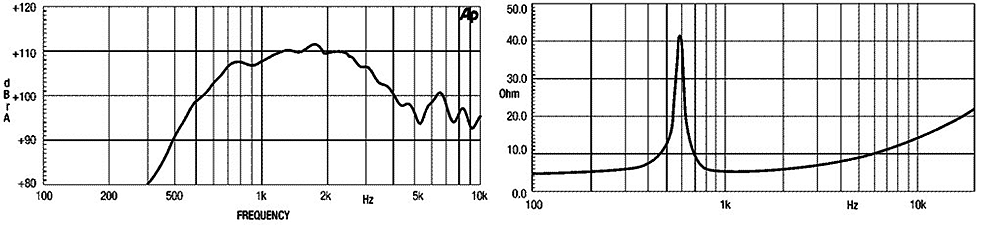

Driver chart

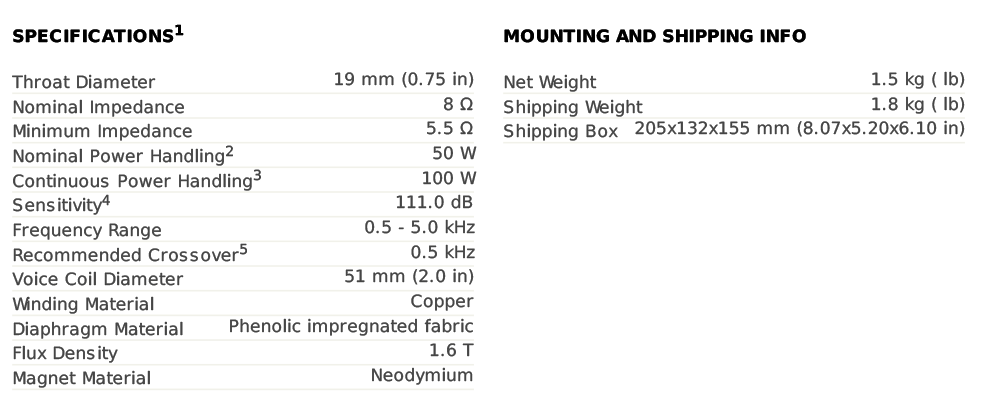

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct