The proprietary treated Nomex former material shows 30% higher value of tensile elongation at working operative temperature (200°C) when compared to Kapton. Moreover, Nomex is suitable to work also in higher moisture contents environments. The bended former is jointed in a sandwich configuration between PEN suspension and the aluminum dome, assuring extended frequency energy transfer for improved response linearity and unparallel reliability. Through careful use of elementary pieces of neodymium magnets, Eighteen Sound engineers have developed a powerful neodymium magnet assembly able to reach 19 KGauss in the gap in a compact and lightweight structure. The motor structure, throughout the precisely coherent phase plug with 3 circumferential slots and copper ring on the pole piece, reduces inductance effects and distortion. Four top plate air ducts were designed to act as a loading chamber for the diaphragm, implementing mid band distortion and response figures. The custom designed O-ring creates a tight seal between the plate and the cover assuring air chamber loading. Excellent heat dissipation and thermal exchange are guaranteed by the direct contact between the magnetic structure and the aluminum cover that allows to obtain a lower power compression value. The ability to perform properly under inclement weather conditions is a key-point of Eighteen Sound philosophy. The special coating applied to the magnet and the top and back plates of the magnetic structure makes the ND1460A compression driver resistant to the corrosive effects of salts and oxidization.

Driver diagram

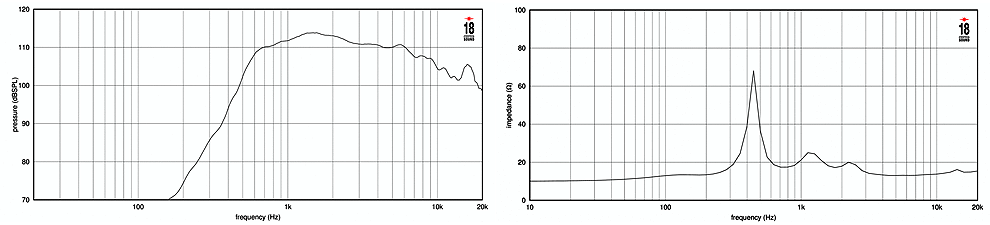

Driver chart

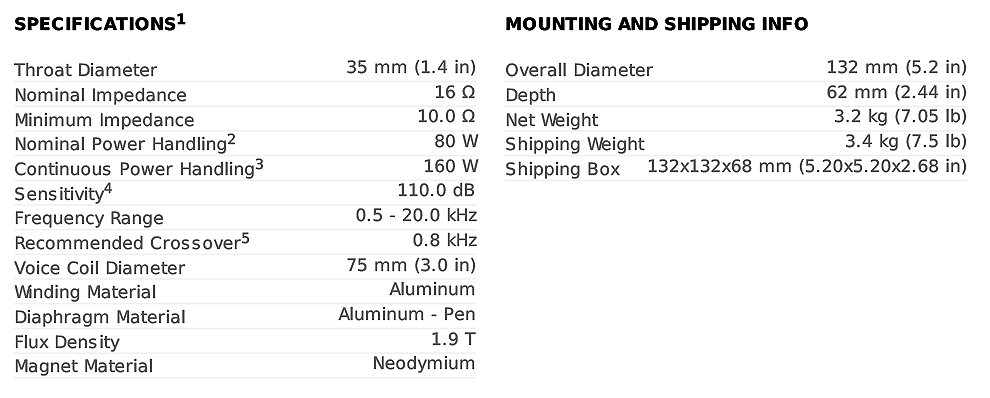

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct