The cone is carried by a double half-roll suspension composed of a material which is more resistant to aging and fatigue than traditional materials, providing the correct damping and excursion control.The 75 mm state-of-the-art voice coil assembly incorporates a fine EDGE-wound aluminum wire together with a strong fiberglas former to get the necessary force factor, mass lightness and high power handling. The voice coil is cooled using airways between the chassis back plate and the magnet face plate, which allow heated air from the voice coil and gap to be channeled away an dissipated by the chassis basket. This technology is another product of 3D CAD resource application by our engineers. The magnetic structure has also been optimized using our in-house FEA CAD resource which has maximized the flux density in the voice coil gap. A special treatment is applied to both the top and back plates making them more resistant to the corrosive effects of salts and oxidation. This treatment is more effective than any other treatment in use today.

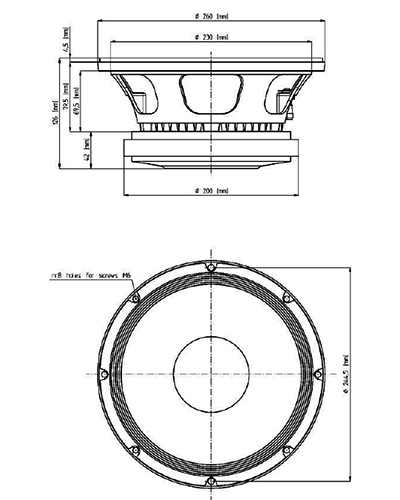

Driver diagram

Driver chart

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct