The levels of force factor and power handling are, as a consequence, at the upper professional level with best power to weight ratio. The 65mm Ø state-of-the-art, edgewound aluminum wire voice coil is wound on a high strength fiberglas former. The voice coil is cooled through airways placed between the chassis back plate and the magnet faceplate and carefully designed ventilation ducts made into the metal back plate. The curvilinear paper cone is formed using a special high strength wood pulp, designed to achieve the best possible rigidity and stiffness. Due to the increasing use during outdoor audio events, the ability to perform in humid environments is an extra key feature of the 10NW650. This is achieved trough an exclusively developed cone treatment which renders the cone humidity repellent while does not increasing the total moving speaker mass. In addition, a special epoxy treatment is applied to the top and back plates making the transducer far more resistant to the corrosive effects of salts and oxidization.

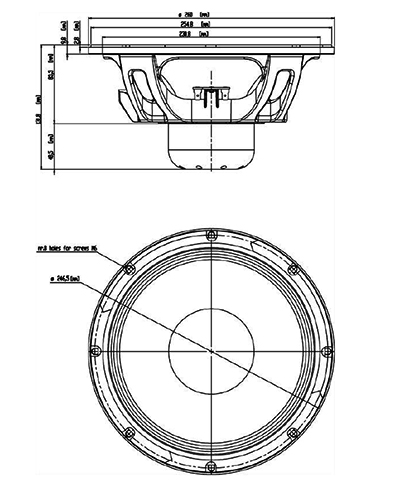

Driver diagram

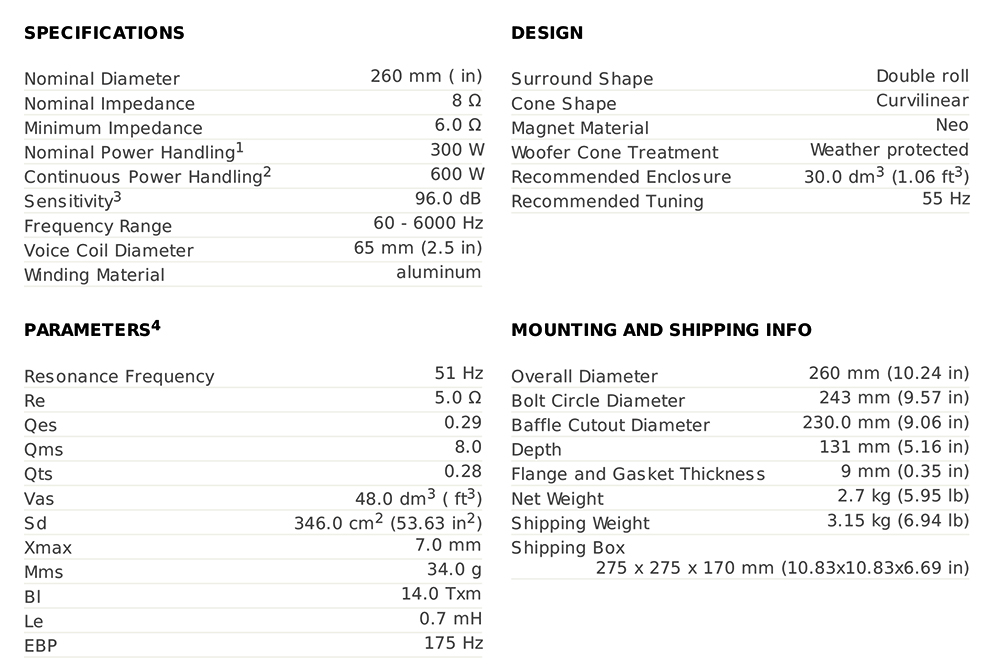

Driver chart

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct