The cone is carried by a M-roll suspension, that provides amazing dampening and excursion control. The state-of-the-art voice coil employs our Interleaved Sandwich Voice coil (ISV) technology, in which a high strength fiberglas former carries windings on both the outer and inner surfaces. By mean of a balanced coil with uniform distribution of mass and motive energy, this technology assures an extremely linear motor assembly. The voice coil cooling has been achieved by incorporating airways between the chassis back plate and the top plate of the magnet which allow heated air from the voice coil and gap to be channeled away and dissipated by the chassis basket. This technology is the result of a meticulous design exercise using a sophisticated in-house 3D CAD facility. The magnetic structure has also been optimized using our in-house FEA CAD resource to maximize flux density in the voice coil gap. Eighteen Sound R&D has developed a special cone treatment specifically dedicated to improve the dampening properties of the moving assembly, thus considerably improving the transient response control. This treatment also gives water repellent properties to the cone, enabling the 12NMB1000 to be used in humid environments without damage.

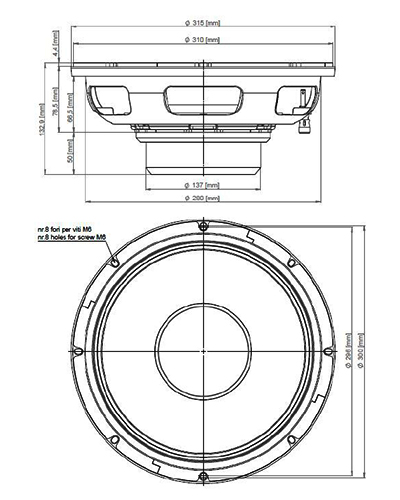

Driver diagram

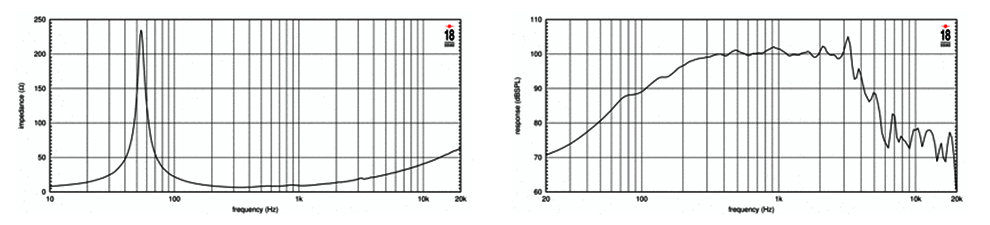

Driver chart

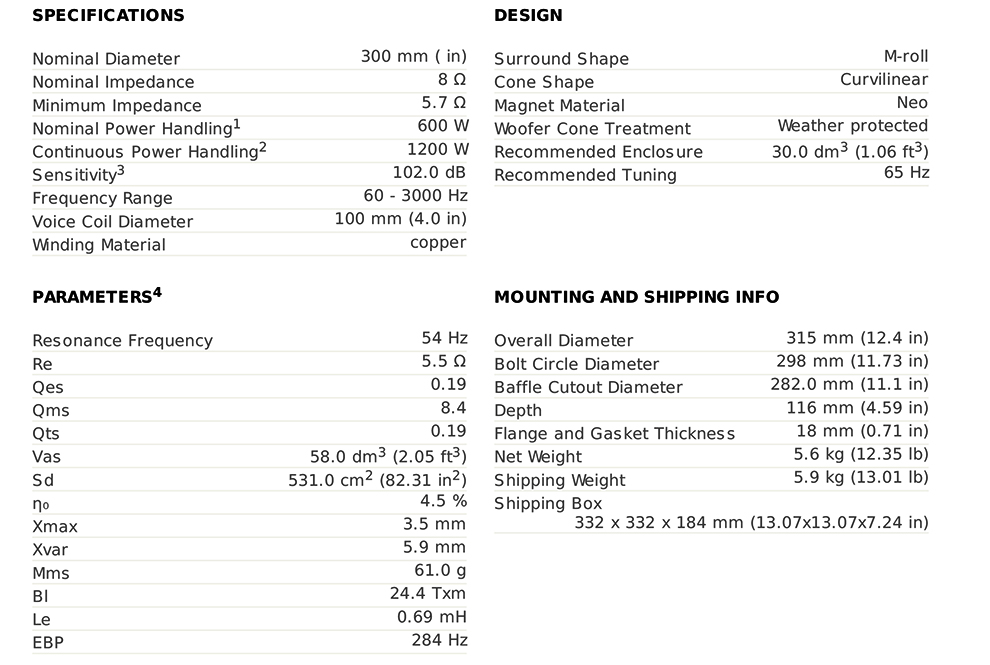

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct