An EDGE-wound aluminum voice coil, wounded on proprietary treated Nomex, completes diaphragm assembly. Proprietary treated Nomex former, thanks to its physical properties, shows 30% higher value of tensile elongation at working operative temperature(200°C) when compared to Kapton. This plus is capable to keep properly energy transfer control to the dome in real working conditions. Moreover, Eighteen Sound voice coil proprietary Nomex former is suitable to work also in environments with higher moisture contents. The polypropylene phase plug is the result of a meticulous design exercise. Its shape assures the correct acoustic impedance of the radiating dome, reducing distortion levels across a very wide range of frequency. Final result is a smooth coherent wavefront in the horn entrance, high thermal stability and manufacturing consistency. The compact and lightweight ceramic magnet assembly has been designed to obtain 16KGauss in the gap. The XD125 pressure die-cast polyurethane foam horn maintains constant nominal 90° Horizontal x 60° Vertical pattern control, providing consistent on-axis and off-axis frequency response from 2kHz to 16kHz in the horizontal plane and from 2,5kHz to 16 kHz in the vertical plane. Horn directivity is constant from 2,5kHz. Computer Aided Finite Element Analysis and extensive testing were used to obtain the horn contours. Horn is designed to be free of resonance and vibrations assuring maximum strength.

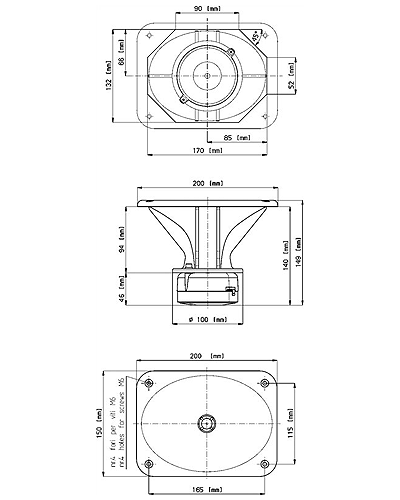

Driver diagram

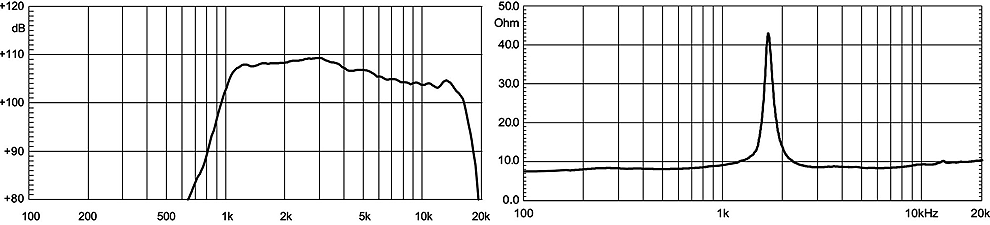

Driver chart

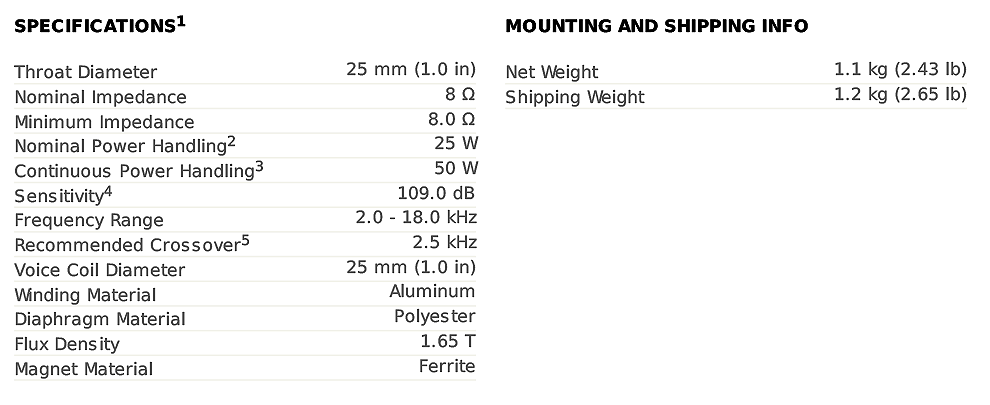

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct