The in-house developed cone treatment is humidity repellent and significantly dampens bell mode resonances. The 75mm (3in) copper EDGE-wound voice coil assembly is wound on a strong fiberglas former to improve force transmission and power handling. The already low distortion and high sound quality are further improved by the aluminum demodulating ring (SDR) used to reproduce instantaneous peak on mid frequencies, reducing intermodulation distortion. The magnetic structure has been optimized using our FEA CAD software that has maximized the flux density in the voice coil gap. Excellent heat dissipation has also been achieved by incorporating air channels between the basket and the magnetic top plate. Due to the increase in use of audio systems at outdoor events, the ability of the 15W930 to perform in adverse weather conditions or in areas of high humidity is a great advantage. This has been achieved using exclusive treatments which enable the cone and the magnetic plate to resist corrosion and render the cone water repellent at the same time.

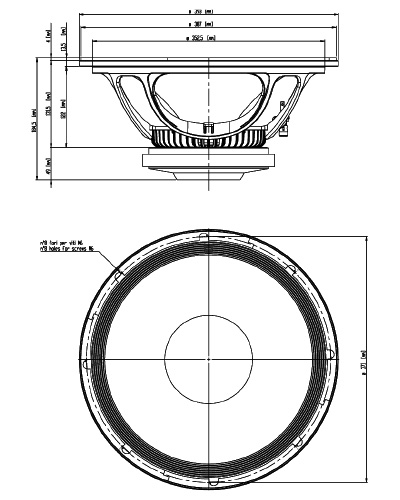

Driver diagram

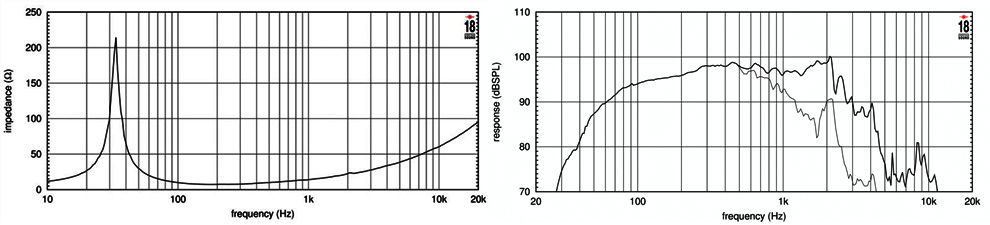

Driver chart

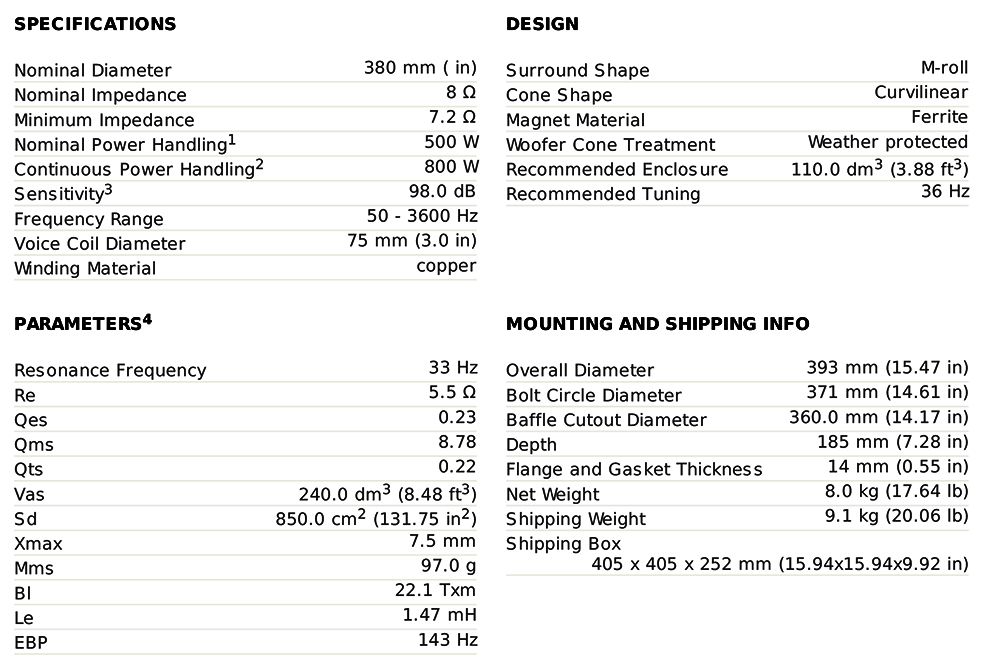

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct