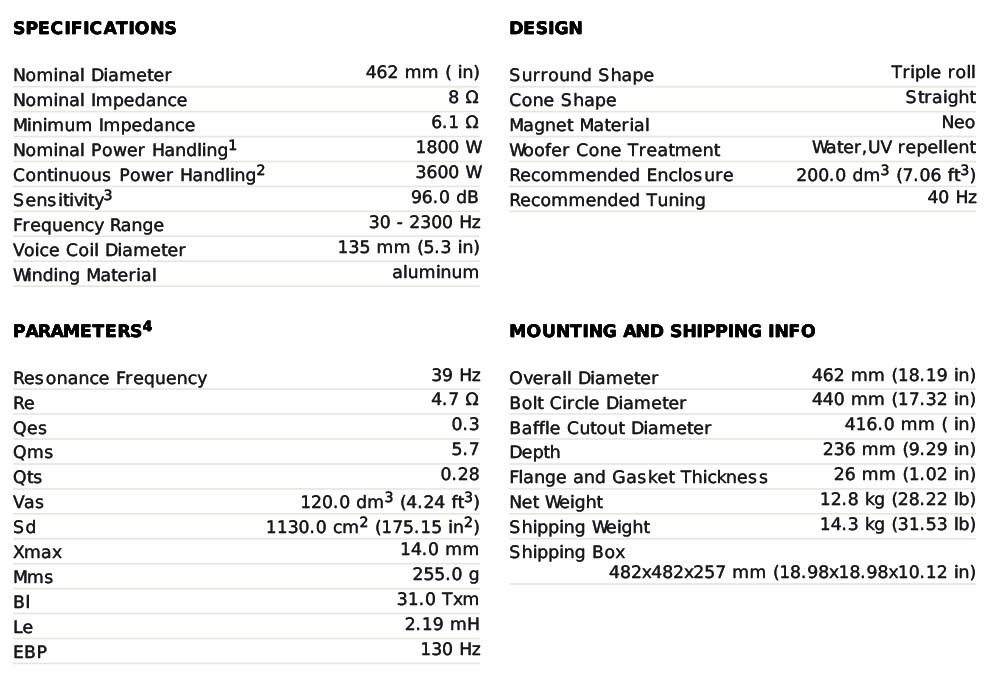

The state-of-the-art 5,3" diameter ISV copper clad aluminum wire CCAW voice coil shows a inside-outside SPLIT winding, four layers design, enabling the 18NLW9601 to handle up to 3600W program power. Bl force factor, as well as all other electro-dynamic parameters, are linear within the working range. This, together with the exceptional high excursion behavior - 70mm before damage, ±14mm linear Xmax - makes the 18NLW9601 an extremely low distortion, highly dynamic transducer. The already low distortion and sound quality have been further improved by the aluminum demodulating ring (SDR technology), that flatten impedance and phase versus frequency. The 18NLW9601 has been developed after intense FEA and fluidodynamics simulation and testing, focusing on dissipating the heat generated by the powerful voice coil. Special attention was given to the optimization of air flow into the gap without introducing audible noise. A low-density foam diffractor placed into the vent hole acts as a cooling system, increasing the power handling capability and lowering the power compression figure. The carbon fiber reinforced, straight ribbed cone shows a proprietary resin treatment for extra pulp strength and water repellent properties. A special coating applied to both the top and back plates makes the transducer far more resistant to the corrosive effects of salts and oxidization.

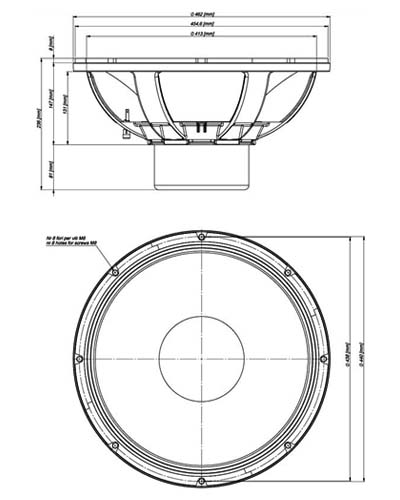

Driver diagram

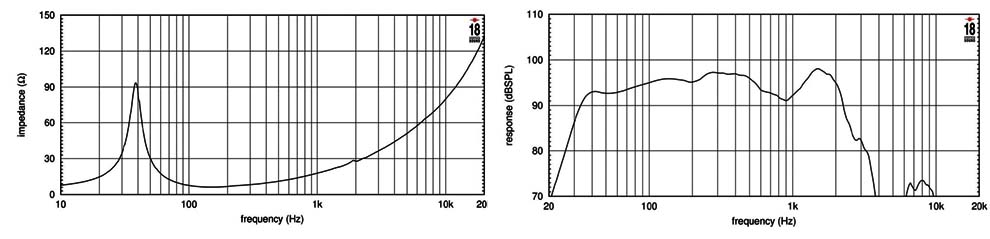

Driver chart

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct