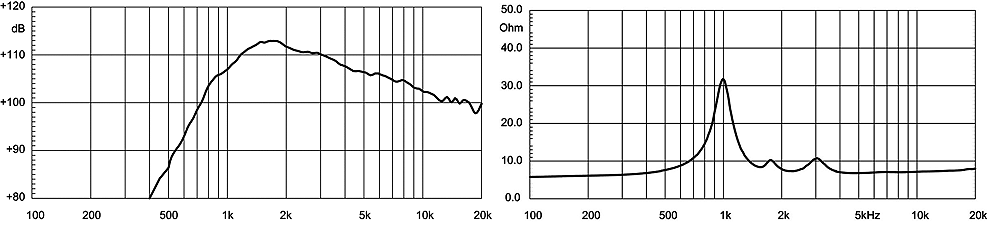

With its very high value of elasticity modulus (six times higher than titanium and two times higher than beryllium), the nitride thin film is capable of doubling the diaphragm overall stiffness with obvious benefits in terms of impulse response and intermodulation distortion reduction. The frequency response is then extended by 25%, showing a predictable, ideal pistonic behavior, avoiding top-end spurious resonances. An

EDGE-wound copper-clad aluminum voice coil, wound on proprietary treated Nomex, completes the diaphragm assembly. Nomex shows a 30% higher value of tensile elongation at a working operative temperature (200°C) when compared to Kapton. Moreover, this proprietary former material is also suitable for use in high moisture content environments. The powerful neodymium magnet assembly has been designed to obtain 20KGauss in the gap giving major benefits in transient response. A copper ring on the pole piece reduces inductance above 10 kHz, improving phase and impedance linearization. The custom designed O-ring creates a tight seal between the plate and the cover assuring air chamber loading. Excellent heat dissipation and thermal exchange are guaranteed by the direct contact between the magnetic structure and the aluminum cover which leads to a lower power compression value. A special treatment has been applied to the magnet and the top and back plates of the magnetic structure making the driver more resistant to the corrosive effects of salts and oxidization.

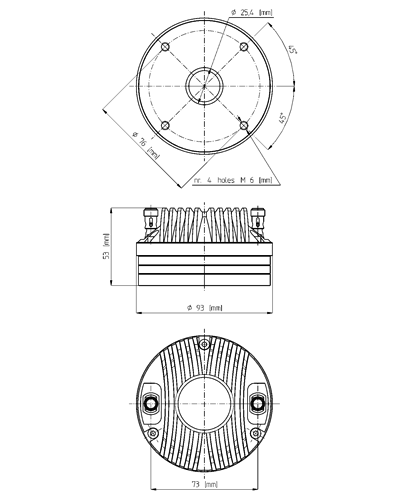

Driver diagram

Driver chart

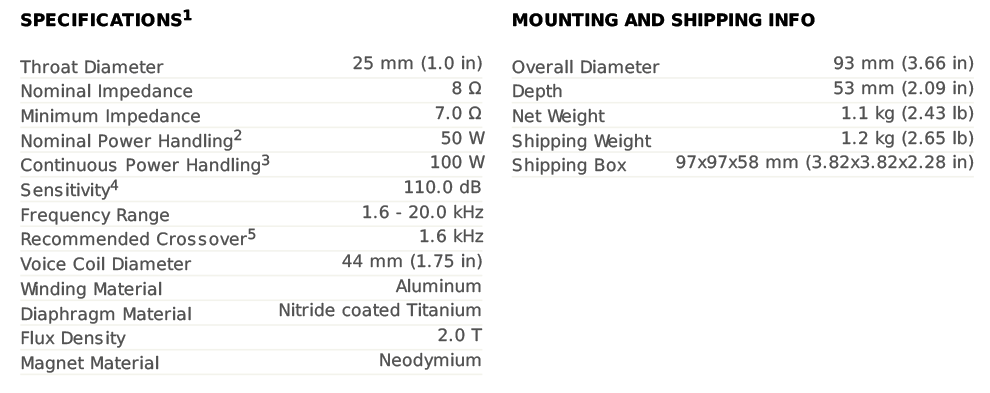

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct