The carbon fiber reinforced curvilinear ribbed cone assures smooth response and exceptional strength with maximum reliability under high mechanical stress. The state-of-the-art voice coil employs our own Interleaved Sandwich Voice coil (ISV) technology, in which a high strength fiberglas former carries windings on both the outer and inner surfaces. This results in a balanced coil with a uniform distribution of mass and motive energy, creating an extremely linear motor assembly. The already low distortion and unmistakable sound quality of this loudspeaker is improved by Double Demodulating Rings (DDR), designed to dramatically reduce the intermodulation and harmonic distortion while improving the transient response. Excellent heat dissipation has been achieved by incorporating air channels between the basket and the magnetic top plate. Maximum flux concentration and force factor in the gap is assured by the unique shape and design of the top and back plates, which have been researched and designed using our in-house magnetic flux FEA CAD resource. Due to the increasing use of high power audio systems at outdoor events or in marine environments, the 18W1300 has been designed to perform properly under inclement weather conditions. This has been achieved using of an exclusive cone treatment which improves pulp strength and gives water repellent properties to both sides of the cone. In addition, a special treatment is applied to the top and back plates which is far more resistant to the corrosive effects of salts and oxidization than any other treatment in use.

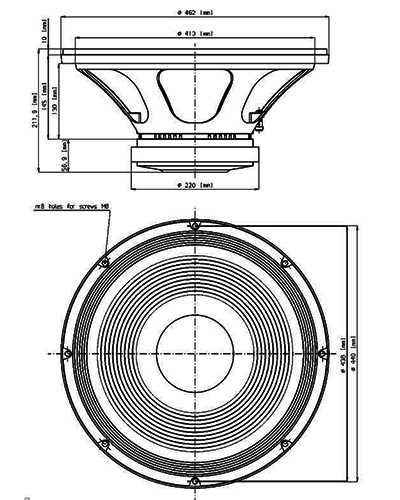

Driver diagram

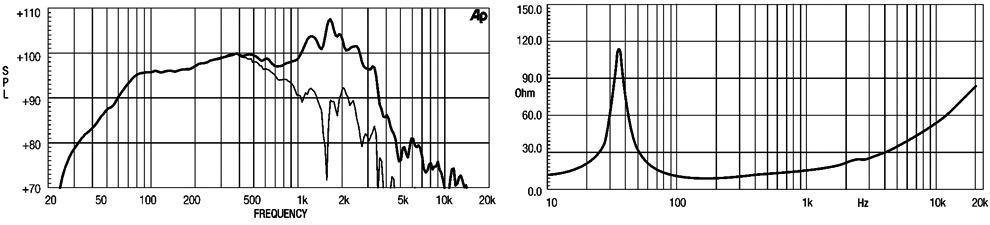

Driver chart

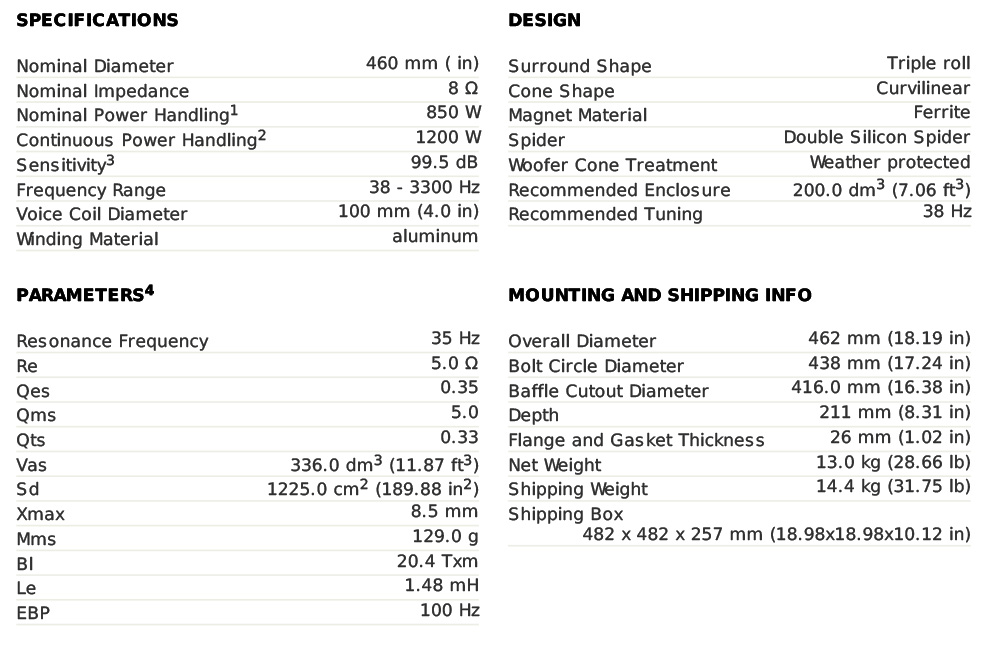

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct