The high quality curvilinear cone assures smooth response and exceptional strength with maximum reliability under high mechanical stress. The 100mm diameter copper wire voice coil employs the Interleaved Sandwich Voice coil (ISV) technology, in which a high strength fiberglas former carries windings on both the outer and inner surfaces to achieve a balanced coil with a uniform distribution of mass and motive energy. This results in an extremely linear motor assembly. Maximum flux concentration and force factor in the gap is assured by the unique shape and design of the top and back plates, which have been researched and designed using our in-house magnetic flux FEA CAD resource. 18W2001 uses the voice coil ventilation technology developed for our flagship 9000 neodymium transducer series. A special low density multi-cell material air diffractor has been placed into the backplate acting as a cooling system, increasing power handling capability and lowering the power compression figure. As a final result Eighteen Sound engineers obtained almost 1 dB reduction in full power power compression value if compared to 18LW1400, and an increased program power handling value of 2400 Watt. 18W2001 is able to perform in adverse weather conditions or in areas of high humidity. This key feature has been achieved using an exclusive water repellent cone treatment and magnetic plate coating which resists against environmental corrosion.

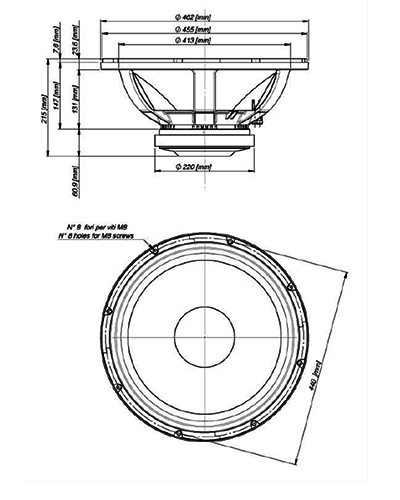

Driver diagram

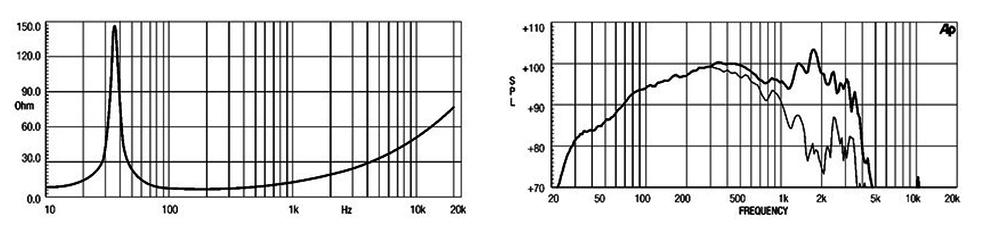

Driver chart

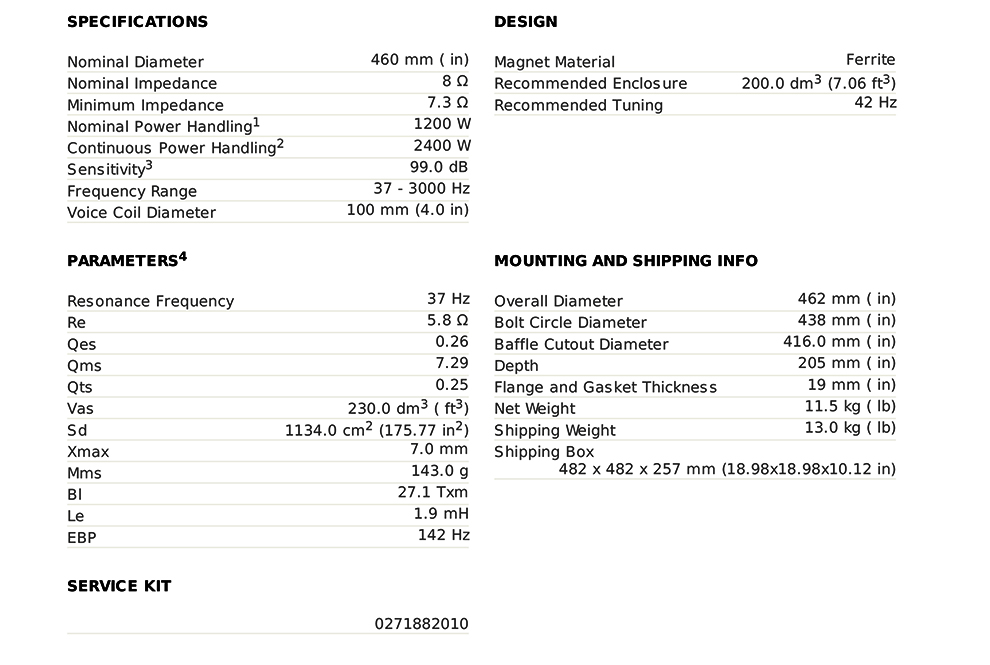

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.